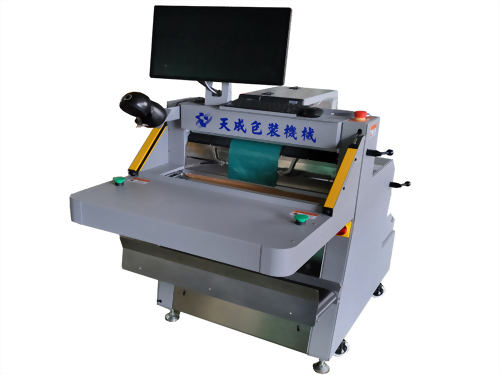

Screw Nut Fully Automatic Weight Bagging Filling Packaging Machine

All Taiwan parts, assembly and manufacturing (Made in Taiwan),Quality is stable.

The structure is durable and easy to maintain.

Option: to link with counter 、 weighter 、labeling or printer、 Grid conveyor、Inclined conveyor、Power Meter...ect, for fully auto packaging system.

ISO 9001 and CE Certified.

**Custom Design Available**

**Net Zero Emissions Custom Design **

-

Suit for large quantity, easy to change bag size.

-

Use PE film, low cost and decrease packaging costs while simplifying the bagging operatione.

-

With optaion: Filling System、 vibratory + counter 、vibratory + weigher (scale)、label machine、printer、conveyor...ect.

-

PLC Human-Machine Interface (HMI).

Screw packaging machine, screw counting bagging packaging machine, Nut counting packaging machine, Nut weighting packaging machine, washer packaging machine, hardware fastener bagging packaging machine, mixed product bagging and packaging machine, screw weight bagging and packaging machine, Kit parts packing system

TianCherng's packaging machines are controlled by PLC, in order to increase production capacity and reduce personnel contact with products again.

TC-950 Bagging Machine can connectable Auto Optical fastener and nuts inspection machines, after sorting direct transports to packaging machine for packaging.

- Suit for large quantity, easy to change bag size.

- Use PE film, low cost and decrease packaging costs while simplifying the bagging operatione.

- With optaion: Filling System、 vibratory + counter 、vibratory + weigher (scale)、label machine、printer、conveyor...ect.

- PLC Human-Machine Interface (HMI).

Screw packaging machine, screw counting bagging packaging machine, Nut counting packaging machine, Nut weighting packaging machine, washer packaging machine, hardware fastener bagging packaging machine, mixed product bagging and packaging machine, screw weight bagging and packaging machine, Kit parts packing system

TianCherng's packaging machines are controlled by PLC, in order to increase production capacity and reduce personnel contact with products again.

TC-950 Bagging Machine can connectable Auto Optical fastener and nuts inspection machines, after sorting direct transports to packaging machine for packaging.

Screw Bagging Packaging Machine: Users can freely set the required packaging count or weight on the machine operation screen. After starting the machine, the feeding vibrator will automatically counting or weighing the material and fill it into the cut plastic bags for sealing and packaging operations; The user can also set the total quantity of packaging required per day. When the total quantity reaches the set value, the machine will notify the user to complete the packaging of the product and stop to wait for the next work order. It is a very simple and clear operation.

Screw Bagging Packaging Machine: Users can freely set the required packaging count or weight on the machine operation screen. After starting the machine, the feeding vibrator will automatically counting or weighing the material and fill it into the cut plastic bags for sealing and packaging operations; The user can also set the total quantity of packaging required per day. When the total quantity reaches the set value, the machine will notify the user to complete the packaging of the product and stop to wait for the next work order. It is a very simple and clear operation.

Screw Magnetic Conveyor: For screws that are easily stuck together, magnetic methods can also be used to effectively separate the products first.

Automatic baggers provide an easy solution for filling and sealing bags containing a wide variety of products. Automatic baggers are the ultimate in reliability and ease of operation. Auto bag making → Counting / Scale (Weighing) → Auto Feeding → Labeling / Printing → Bag Sealing → Finished product bag.

**Custom Design Available**

1~8 pack/min (according to Bag size and feeding speed are different),

Loading max 8kg/pack

220V /380V /415V, 3φ

5 kg/cm²

L1750 x W1310 x H1150 mm Weight : 300 kg

L80~300 mm;W120~300 mm